Transport

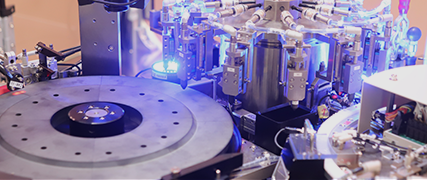

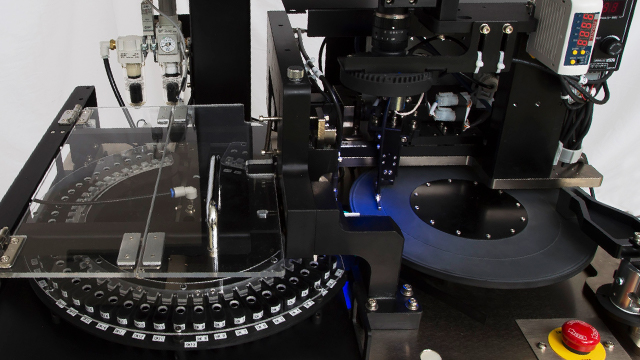

1. MLCC transport technology

World’s fastest processing capacity

22,000 inspection / 1 minute realized

MLCC (Multi-Layer Ceramic Capacitor) is small to very small parts ranging from a few millimeters to 0.1 mm in size. Chip capacitor, etc. are also called. In order to convey this part at high speed, first insert MLCCs one by one in the correct direction in all the small holes (called pockets) of the transportation disc with a small hole of a few thousand holes. Although it seems impossible to think a bit, MLCC automatic sorting machine which measures and classifies 22,000 pieces per minute realized because this became possible.

In this method, first, MLCC is placed in a narrow space (called a bucket) adjacent to the transportation disk, an air flow is generated in the space, and the MLCC is blown up and stirred. At the same time, it generates air flow to suck into the pocket of the transport disk. With the action of these two air flows, you can insert the MLCC in the pocket of the transport disc in the correct orientation. Moreover it is possible to insert in multiple pockets at the same time. I call this mechanism an air bucket. It is one of our patented technologies.

Before the air bucket was devised, MLCC was aligned in one row with parts feeder and transported, and inserted one by one into the pocket of the transfer disk. The parts feeder is to convey small parts while aligning them, and it is still used in many fields even now, but it was difficult to insert it in multiple pockets at the same time, which hampered speed improvement . In order to realize high-speed processing, this air bucket was devised after many trial and error thought that it was necessary to have multiple means for simultaneous insertion.

The number of simultaneous insertion by the air bucket was also 4 at the same time at the beginning, but now it is possible to insert 8 simultaneously, realizing the world’s fastest speed.

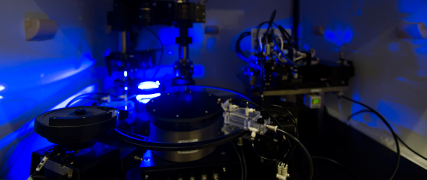

2. Crystal blank conveyance technology

A very small inspection target object,

Do not arrange, carry accurately while scattered

Crystal blank is quartz crystal piece with a thickness of several tens of microns to several microns, from several millimeters to 1 millimeter in length and width. Like glass, it is transparent or semitransparent and very fragile, and you need to pay close attention to the conveyance. In our company, after scattering the crystal blanks to the supply stage separately, the respective positions are detected by the camera, the position is picked up by the nozzle at the tip of the transfer arm using the position information, and accurately transferred one by one to the measuring station To do.

Traditionally, as with MLCC, the crystal blanks were aligned one by one with a parts feeder and then transported to the measuring station. However, because the parts feeder is transported by vibration, when the quartz blank is small and the thickness becomes extremely thin, vibration is difficult to convey because it is too light, it can not be conveyed, it is too thin, clogging with each other, clogging each other, It became difficult to align the blanks and supply them to the measuring station. So, if you can not arrange it, I switched the idea after leaving it scattered.

In our equipment, we will transport the crystal blanks scattered on the supply stage to the measuring station, avoiding those that overlap. And if only the ones that overlap the supply stage remain, we will transfer the non-overlapping crystal blanks after vibrating the supply stage and scattering the overlap.

-

Transport

With ultra-compact MLCC and technology to transport quartz blanks with a thickness of several microns quickly and accurately, we achieve the world’s fastest processing capacity in each field.

-

Control

Control technology that can be said to be the brain of an automatic machine. Our control technology optimizes the measurement and equipment operation and achieves high processing speed.

-

Image processing

By using lighting optimized for the object to be measured and a unique algorithm, it will surely detect its state even transparent or translucent crystal blanks.

-

System technology

Knowledge and technology that can integrate conveyance technology, measuring instruments, control technology, and image processing technology and optimize it over the entire system HUMO Automatic sorting machine is essential.

-

Instrument

Our proprietary measuring instruments are the leading masters to maximize the performance of automatic sorting machines.

HUMO Products / Services

-

Crystal part related equipment

We propose the best performance equipment for each process from crystal blank process to final test.

-

Ceramic capacitor related equipment

We offer the highest cost performance with MLCC automatic sorting machine of the world’s fastest. From now on, I will continue evolving toward the world’s best.

-

Measuring instrument

Instruments that are not in the world, the best for automatic sorting machines, have become leading figures to maximize the performance of automatic sorting machines.

-

Customization / calibration service

We will respond by semi order from standard specification so that optimum inspection according to device characteristics can be done. Please use our proofreading service so that we always inspect it correctly.

Fabless principle to concentrate on technology development

In our Humor Laboratory, we always use the latest and most effective techniques

In order to develop the equipment that demonstrates the best performance, concentrate the resources of the in-house engineer on planning, development and maintenance,

We are using the fabless method to outsource manufacture of equipment to our partner companies.

This enables us to respond accurately and speedily to the needs of our customers and to provide the latest technology born out of needs,

It is easy to offer it to customers again.