Visual Inspection Technology

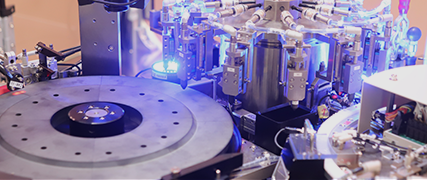

Visual inspection of mirror-finished parts (patent pending)

Even the slightest defect on mirrored or curved surfaces is not overlooked.

More certain than the human eye.

As the term “mirror-finished parts” implies, the surface of the workpiece is finished like a mirror and reflects light, making it difficult to detect defects such as dents and scratches. It was said that it was difficult to stabilize inspection accuracy.

In order to automate this process, we have developed a method to detect defects based on the distortion of the reflected pattern by projecting the pattern onto the workpiece. Since our method can detect defects without moving the workpiece, the detection conditions are stable and even defects that are difficult to detect with the human eye can be reliably detected.

In addition, human judgment is uneven in judging the pass/fail of detected defects. Our system eliminates the unevenness of the human eye by using a small number of machine-learning judgments to target certain patterns.

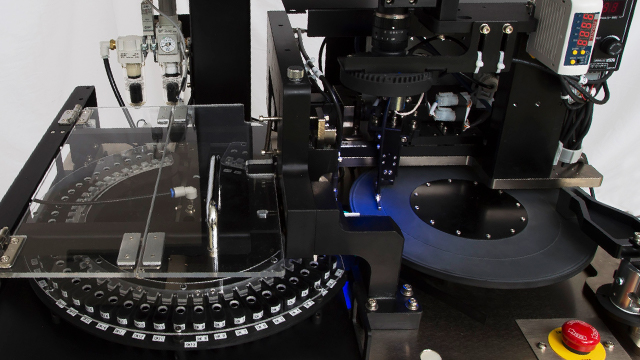

Visual inspection of processed parts

No defects are overlooked with reliable image analysis technology.

Defects such as holes of several tens of microns that occur on the machining marks of metal parts are checked by the human eye, and it has been difficult to automate this process. This is because it is difficult to find defects that are assimilated with machining marks, and defects are judged based on sensory criteria such as “this much” rather than NG if there is even a slight defect.

Our image processing can separate and process processing marks and automatically detect defects by using an ingenious light source and image analysis. By using machine learning to make an intermediate judgment + an algorithm that optimizes judgment criteria such as size, shape, and color to make a final judgment, we were able to make a judgment of several microns with only about 100 samples registered, and to make a judgment with reliable criteria that is not “this much.

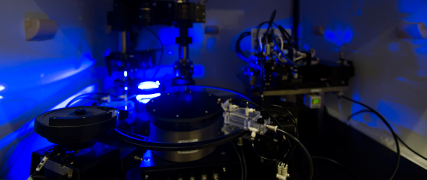

Visual inspection of crystal blanks

Finding defects on transparent and translucent objects.

Toward Image Detection Beyond the Human Eye

Crystal blanks, such as glass pieces ranging from several millimeters to less than one millimeter in length and width and several tens of microns to several microns in thickness, are translucent or transparent, which means that light is polarized and transmitted through them, making it difficult to detect scratches or discoloration on them. Our automatic sorting machine can detect them automatically by using an ingenious light source and algorithm.

Defects that can be detected by this automatic sorter include chips, scratches, chipping, cracks, stains (discoloration), and abnormal corner angles and areas. In order to detect multiple defects, an imaging environment (light source) appropriate for each type of defect is required. We can detect multiple defects simultaneously by separating and processing multiple images based on color information from a single image under multiple light sources. Also, although lapped crystal blanks are translucent, defects are detected using an algorithm that cancels out the effects of material texture and individual differences.

Frequency, capacitance, and leakage current measurements have common pass/fail criteria in the form of numerical values, but image inspection has ambiguity in pass/fail judgment, and it is said that there is nothing better than the human eye. However, since the human eye has an unevenness in detection, an automatic sorting machine has been desired. Our equipment will continue to evolve with the goal of “someday surpassing the human eye.

-

Transport

With ultra-compact MLCC and technology to transport quartz blanks with a thickness of several microns quickly and accurately, we achieve the world’s fastest processing capacity in each field.

-

Control

Control technology that can be said to be the brain of an automatic machine. Our control technology optimizes the measurement and equipment operation and achieves high processing speed.

-

Image processing

By using lighting optimized for the object to be measured and a unique algorithm, it will surely detect its state even transparent or translucent crystal blanks.

-

System technology

Knowledge and technology that can integrate conveyance technology, measuring instruments, control technology, and image processing technology and optimize it over the entire system HUMO Automatic sorting machine is essential.

-

Instrument

Our proprietary measuring instruments are the leading masters to maximize the performance of automatic sorting machines.

HUMO Products / Services

-

Crystal part related equipment

We propose the best performance equipment for each process from crystal blank process to final test.

-

Ceramic capacitor related equipment

We offer the highest cost performance with MLCC automatic sorting machine of the world’s fastest. From now on, I will continue evolving toward the world’s best.

-

Measuring instrument

Instruments that are not in the world, the best for automatic sorting machines, have become leading figures to maximize the performance of automatic sorting machines.

-

Customization / calibration service

We will respond by semi order from standard specification so that optimum inspection according to device characteristics can be done. Please use our proofreading service so that we always inspect it correctly.

Fabless principle to concentrate on technology development

In our Humor Laboratory, we always use the latest and most effective techniques

In order to develop the equipment that demonstrates the best performance, concentrate the resources of the in-house engineer on planning, development and maintenance,

We are using the fabless method to outsource manufacture of equipment to our partner companies.

This enables us to respond accurately and speedily to the needs of our customers and to provide the latest technology born out of needs,

It is easy to offer it to customers again.