Instrument

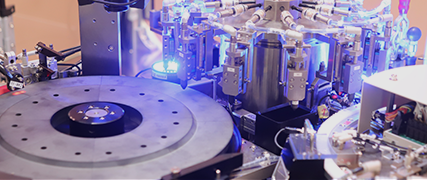

All-solid-state battery charge/discharge measurement system

A charge-discharge measurement system to test the safety and durability of next-generation batteries

All-solid-state batteries have improved safety and durability since the electrolyte was changed from liquid to solid, but in order to inspect their high product specifications, a measurement system consisting of a low-noise power supply unit that can be controlled in units of several mV and a current measurement unit that can accurately measure currents of several pA is required.

Our company has a 45-year history of MLCC measurement systems, and by applying the ultra-low noise high-voltage power supply and high-resolution micro-current measurement technologies developed for MLCC withstand voltage and insulation resistance measurement systems, we have achieved the 5mA charge/discharge capability required for all-solid-state battery measurement, a constant-current constant-voltage charge/discharge circuit with output voltage accuracy of FS 0.1%, and current measurement with FS 0.3% accuracy. The result is a constant-current, constant-voltage charging/discharging circuit with an output voltage accuracy of FS 0.1%, and current measurement with an accuracy of FS 0.3%.

The current measurement section is a compact circuit board with 20 channels, and by combining 20 of these boards, the system can measure 400 all-solid-state batteries simultaneously. Furthermore, by installing multiple units of this measurement system in an automatic inspection system, it is possible to flexibly construct a space-saving, high-process automatic inspection system.

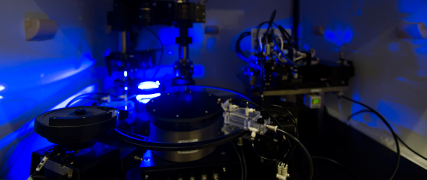

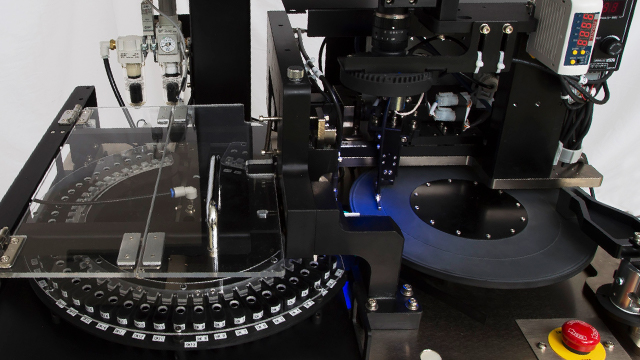

Withstand voltage / insulation resistance measurement system

To inspect the highest standards of products,

Developed the highest standard of withstand voltage / insulation resistance measurement system

It is a system developed in-house for measuring withstand voltage and insulation resistance of MLCC which consists of ultra-low noise high voltage power supply part and high resolution micro current measurement part.

In order to measure the withstand voltage and insulation resistance of MLCC, the noise of the high voltage power supply part is extremely small (on the order of μV), it is possible to charge and discharge the MLCC at a high speed with a constant current, and there is no voltage and current overshoot ( The voltage is 0.1 V, the current is 1 mA or less), the abnormality does not occur even if the output of the high voltage power supply section is repetitively shorted, the low current measurement section is low input impedance (100 Ω or less), the connection with the MLCC can be detected Technically high hurd is required such as existence (detectable even with 0.5 pF MLCC). In addition to being a high-speed and high-accuracy measurement system that satisfies all of these requirements, the latest model developed in-house is designed to be able to freely combine a plurality of high-voltage power supply sections and minute current measurement sections It enables various measuring methods. Measurement can be configured according to the characteristics of MLCC, such as a configuration that performs measurement after multiple consecutive charging, and configuration that repeats charge → measurement → discharge.

MLCC required longer charging time as the capacity became larger, so the processing capacity of the sorter was declining because of that, earn charging time by charging multiple times, realizing high speed processing even for large capacity MLCC To do.

Our company has a history of withstanding voltage and insulation resistance measuring equipment for 40 years. We continue to evolve with the theme of how fast and accurate the inspection required for MLCC accuracy assurance is done.

-

Transport

With ultra-compact MLCC and technology to transport quartz blanks with a thickness of several microns quickly and accurately, we achieve the world’s fastest processing capacity in each field.

-

Control

Control technology that can be said to be the brain of an automatic machine. Our control technology optimizes the measurement and equipment operation and achieves high processing speed.

-

Image processing

By using lighting optimized for the object to be measured and a unique algorithm, it will surely detect its state even transparent or translucent crystal blanks.

-

System technology

Knowledge and technology that can integrate conveyance technology, measuring instruments, control technology, and image processing technology and optimize it over the entire system HUMO Automatic sorting machine is essential.

-

Instrument

Our proprietary measuring instruments are the leading masters to maximize the performance of automatic sorting machines.

HUMO Products / Services

-

Crystal part related equipment

We propose the best performance equipment for each process from crystal blank process to final test.

-

Ceramic capacitor related equipment

We offer the highest cost performance with MLCC automatic sorting machine of the world’s fastest. From now on, I will continue evolving toward the world’s best.

-

Measuring instrument

Instruments that are not in the world, the best for automatic sorting machines, have become leading figures to maximize the performance of automatic sorting machines.

-

Customization / calibration service

We will respond by semi order from standard specification so that optimum inspection according to device characteristics can be done. Please use our proofreading service so that we always inspect it correctly.

Fabless principle to concentrate on technology development

In our Humor Laboratory, we always use the latest and most effective techniques

In order to develop the equipment that demonstrates the best performance, concentrate the resources of the in-house engineer on planning, development and maintenance,

We are using the fabless method to outsource manufacture of equipment to our partner companies.

This enables us to respond accurately and speedily to the needs of our customers and to provide the latest technology born out of needs,

It is easy to offer it to customers again.